The Role of Ceramic Coating in Safeguarding Your Vehicle's Paint From Environmental Damage

Ceramic finishing has arised as an advanced service for automobile owners looking for to protect the honesty of their automobile's outside. As we explore the nuances of ceramic finish, it becomes noticeable that the option to implement this protective measure might substantially influence your automobile's durability and visual.

What Is Ceramic Coating?

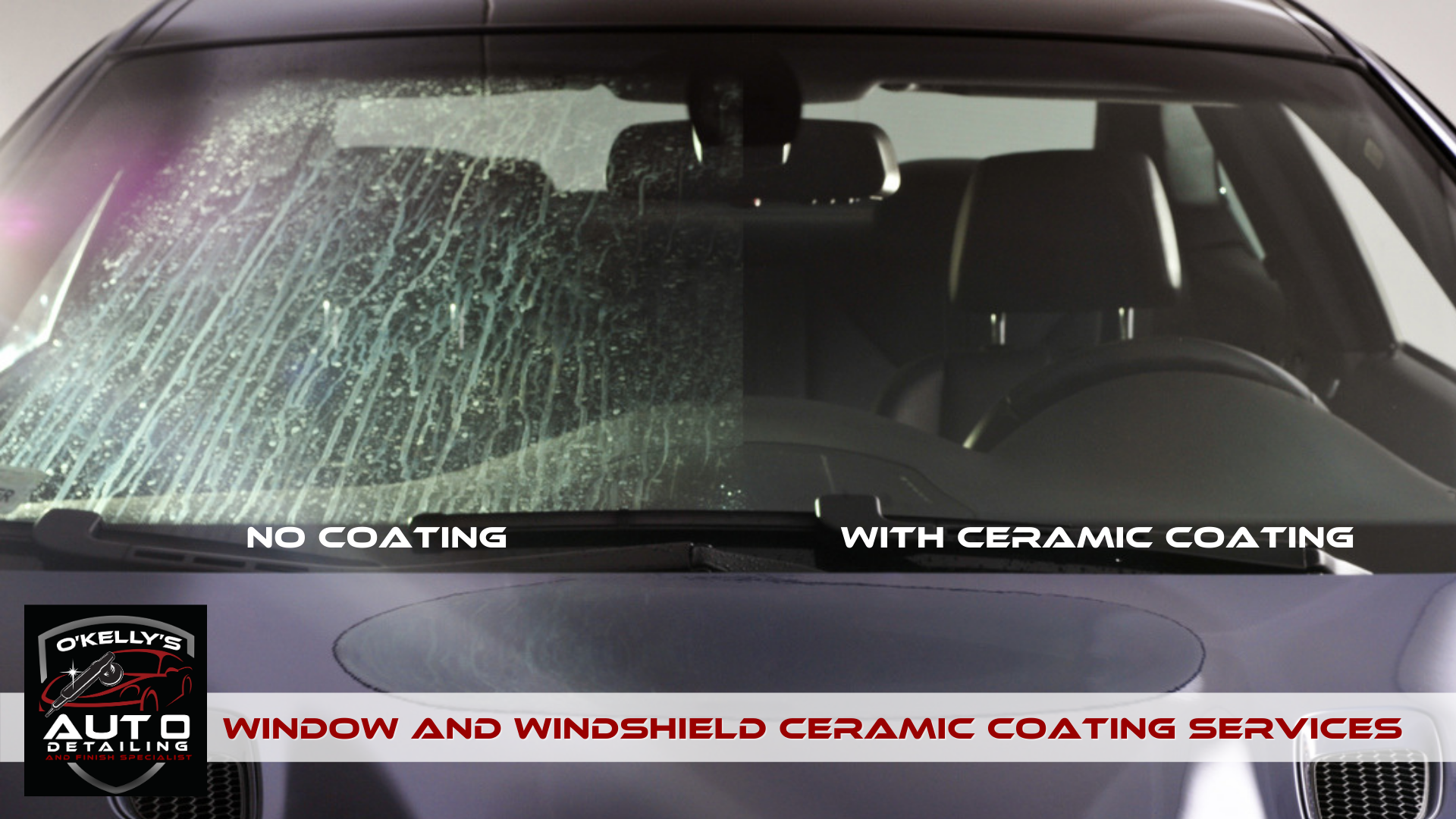

Ceramic coating is an advanced liquid polymer used to the exterior surfaces of a lorry, created to provide a durable layer of protection for the paint. This ingenious solution forms a chemical bond with the car's manufacturing facility paint, creating a hydrophobic and durable shield. The finishing contains nanoparticles that complete the tiny flaws in the paint, leading to a smooth surface that enhances gloss and radiate.

Normally, ceramic coverings are offered in different solutions, permitting various degrees of protection and long life. While some products can last for a number of months, others provide protection for a number of years, depending on the thickness of the application and ecological factors. The application process requires careful prep work, including washing, decontaminating, and brightening the car's surface area to make certain ideal bond of the finish.

Benefits of Ceramic Layer

One of the primary benefits of applying a ceramic coating is the remarkable defense it offers to automotive paint. This advanced finish forms a long lasting layer that guards the car's surface from a range of ecological hazards, including UV rays, acid rainfall, bird droppings, and tree sap. By providing this robust defense, ceramic finishings significantly decrease the risk of fading and etching, maintaining the cars and truck's visual charm over time.

Along with protection, ceramic coatings are renowned for their hydrophobic properties, which push back water and dust, making it less complicated to keep a clean car. This self-cleaning result reduces the regularity of cleaning, saving both time and sources. In addition, ceramic finishes boost the depth of the paint's gloss, causing a sleek and vibrant appearance that boosts the general appearance of the vehicle.

An additional noteworthy advantage is the durability of ceramic coverings. Unlike conventional waxes or sealants that call for frequent reapplication, ceramic finishings can last several years, offering an affordable option for cars and truck proprietors seeking long-term security. Overall, investing in ceramic finish leads to boosted resilience, lowered maintenance, and sustained aesthetic allure for automobile paint.

Just How Ceramic Coating Functions

A ceramic layer operates with a chemical bonding process that produces a protective layer on the automobile's paint surface area. This ingenious remedy utilizes innovative nanotechnology, where microscopic particles of silica are suspended in a fluid type - ceramic coating. Upon application, these particles bond with the manufacturing facility paint, creating a hydrophobic and durable layer that enhances the vehicle's surface

The major element of ceramic layers, silicon dioxide (SiO2), adds to the finishing's toughness and resilience. When treated, the covering click site transforms right into a difficult, glass-like coating that shields the paint from environmental impurities such as dirt, UV rays, bird droppings, and tree sap. This molecular bond leads to a surface that is not just resistant to scrapes but likewise much easier to clean up, as dust and crud are less likely to adhere.

Furthermore, the hydrophobic homes of ceramic coatings cause water to grain and slide off, reducing the chances of water areas and mineral deposits. This safety obstacle efficiently extends the life of the paint and preserves the automobile's aesthetic allure, supplying my company car proprietors a resilient service for paint defense.

Application Refine of Ceramic Coating

When thinking about the application of ceramic finishing, prep work is vital to attaining optimum results. Any type of flaws or scrapes must be addressed at this phase, as the finish will certainly bond with the surface area beneath.

Ceramic coating is after that applied in tiny areas, typically utilizing an applicator pad. It is essential to operate in also strokes, making sure uniform protection. The layer must be allowed to cure for a specified time, which can differ depending on the item used. After the preliminary application, a top notch microfiber towel is used to rub the surface area, improving gloss and making sure a smooth finish. The vehicle needs to be left to heal in a controlled setting to enable the layer to totally bond with the paint.

Long-Term Maintenance and Treatment

Attaining an effective ceramic finish application establishes the structure for lasting security, however correct pop over to this web-site maintenance is crucial to protecting its benefits. Routine cleaning is necessary; using a pH-neutral vehicle shampoo will certainly assist maintain the finish's integrity without causing damage. Prevent automated auto cleans that use rough products, as they can endanger the layer's surface area.

Moreover, using a ceramic layer maintenance spray can improve the existing layer, giving an additional boost in protection and shine. It's recommended to execute this every three to 6 months, relying on environmental direct exposure.

Finally, vehicle parking in shaded areas or making use of automobile covers can protect against extended direct exposure to damaging UV rays and ecological contaminants, further prolonging the life of your ceramic coating. By sticking to these upkeep techniques, you can guarantee your lorry's surface stays protected and aesthetically appealing for many years to come.

Verdict

In summary, ceramic layer works as an important protective procedure for vehicle paint, effectively securing vehicles from a variety of environmental dangers. Its capability to produce a durable hydrophobic barrier not only improves aesthetic appeal yet also substantially lowers the frequency and intensity of maintenance called for. The lasting nature of this innovative polymer highlights its value in preserving vehicle honesty and appearance, eventually adding to a more long lasting and visually enticing vehicle surface.

Ceramic finish is an advanced fluid polymer applied to the outside surfaces of a lorry, made to supply a long lasting layer of protection for the paint. Ceramic coverings boost the deepness of the paint's gloss, resulting in a sleek and lively appearance that elevates the overall appearance of the lorry.

A ceramic layer runs through a chemical bonding process that produces a protective layer on the automobile's paint surface.The main element of ceramic finishings, silicon dioxide (SiO2), adds to the layer's toughness and durability.In recap, ceramic finish serves as a crucial protective procedure for automobile paint, successfully shielding cars from a range of environmental hazards.

Comments on “Ceramic Coating vs. Traditional Wax: Which is Right for Your Vehicle?”